Standard Masking Solutions

Silicone Leading Pull Plug – Reusable Protection up to 315ºC

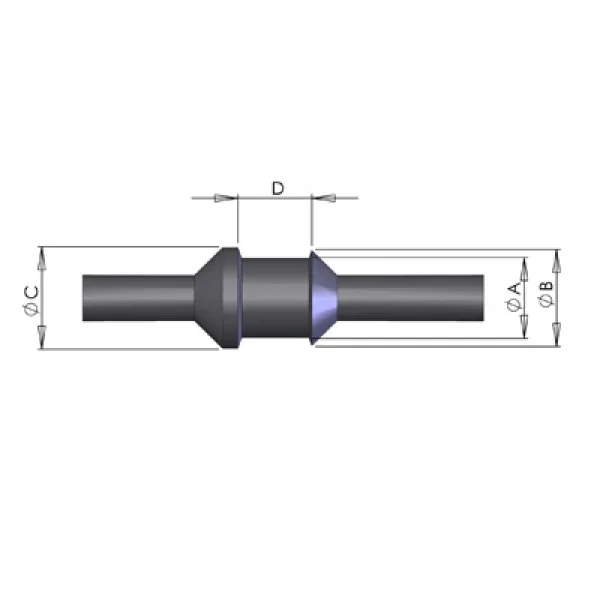

Silicone Leading Pull Plugs are designed to protect threaded through holes and the first thread on both sides during surface finishing and coating processes. These LT200 Silicone Plugs feature a threaded dual-end body with a leading guide tip and pull handle, ensuring perfect alignment and tight sealing. Made from high-quality reusable silicone, they are resistant up to 315ºC and provide accurate, clean and reliable masking results.

Key Features and Advantages of Silicone Leading Pull Plugs

- High temperature resistance up to 315ºC, ideal for powder coating, liquid coating and plating.

- Leading guide design improves centering and insertion through threaded holes.

- Protects both sides by covering the first thread on each end of the through hole.

- Pull-handle system allows fast and easy installation and removal without tools.

- Reusable and flexible, maintaining sealing accuracy after multiple masking cycles.

Applications of Reusable Silicone Leading Pull Plugs

LT200 Silicone Leading Pull Plugs are used in Powder Coating, Liquid Coating, Plating, E-Coating, Anodizing and Cataphoresis. Their dual-threaded leading design ensures precise masking and secure sealing for threaded through holes that require protection on both sides.

Durability and Reusability of 315ºC Silicone Leading Pull Plugs

Manufactured from premium silicone, these plugs maintain elasticity and dimensional accuracy even after repeated high-temperature cycles. They provide a cost-effective and sustainable masking solution for threaded hole protection during industrial coating and plating processes.

Choose the LT200 – Reusable Silicone Leading Pull Plug 315ºC for precise, reusable and professional masking in all surface treatment applications.