Standard Masking Solutions

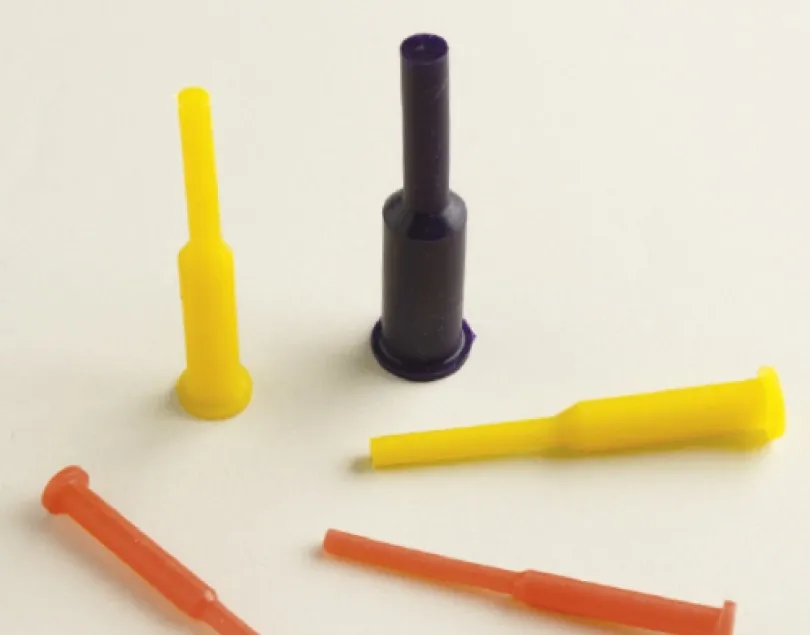

Silicone Weld-Nut Pull Plug – Reusable Protection up to 315ºC

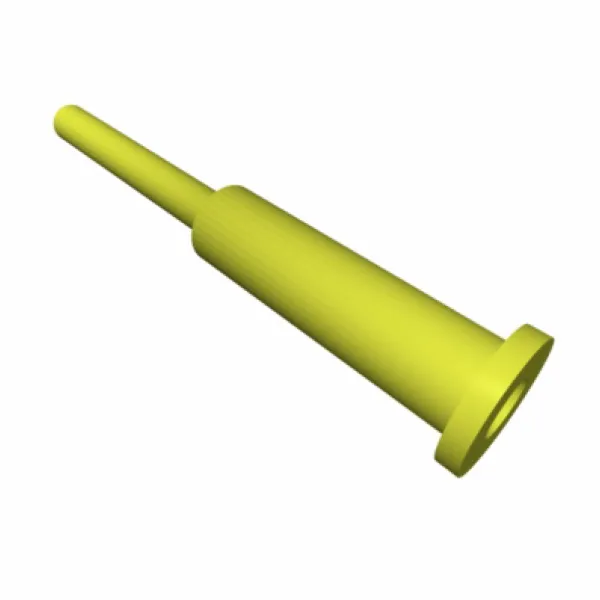

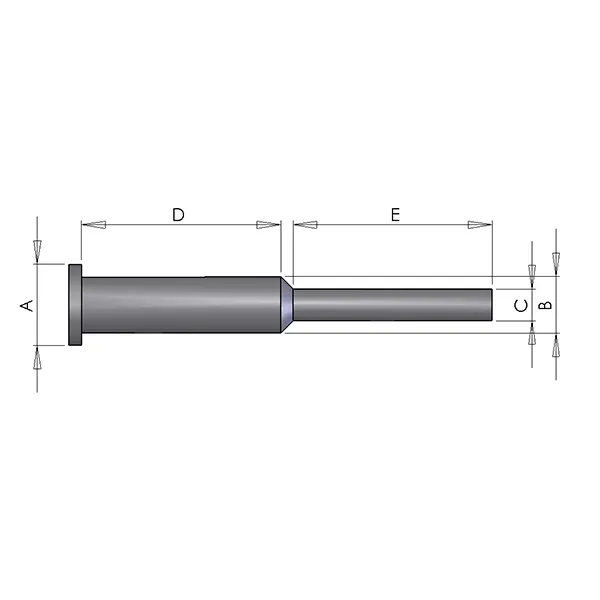

Silicone Weld-Nut Pull Plugs are designed to protect holes and chamfers during surface treatment and coating processes. These WP Silicone Plugs feature a cylindrical body with an integrated pull handle for easy insertion and removal through the hole. Made from high-quality reusable silicone, they are resistant up to 315ºC and ensure accurate, clean and efficient masking results.

Key Features and Advantages of Silicone Weld-Nut Pull Plugs

- High temperature resistance up to 315ºC, ideal for powder coating, liquid coating and plating.

- Flanged head design covers the chamfer and ensures complete protection of the hole opening.

- Pull-through handle enables fast application and easy removal without tools.

- Reusable and flexible, maintaining fit and performance after multiple masking cycles.

- Suitable for through holes and weld-nut applications requiring both internal and external protection.

Applications of Reusable Silicone Weld-Nut Pull Plugs

WP Silicone Weld-Nut Pull Plugs are used in Powder Coating, Liquid Coating, Plating, E-Coating, Anodizing and Cataphoresis. Their cylindrical body and flanged head protect both the internal thread and surrounding chamfer, ensuring a clean, professional finish after coating or plating.

Durability and Reusability of 315ºC Silicone Weld-Nut Pull Plugs

Manufactured from durable silicone, these plugs retain flexibility and precision after repeated exposure to high temperatures. They provide a cost-effective and sustainable masking solution for protecting holes and chamfered areas in industrial finishing processes.

Choose the WP – Reusable Silicone Weld-Nut Pull Plug 315ºC for efficient, reusable and precise masking performance in all coating and surface treatment applications.