Standard Masking Solutions

Silicone Hollow Tapered Plug – Reusable Protection up to 315ºC

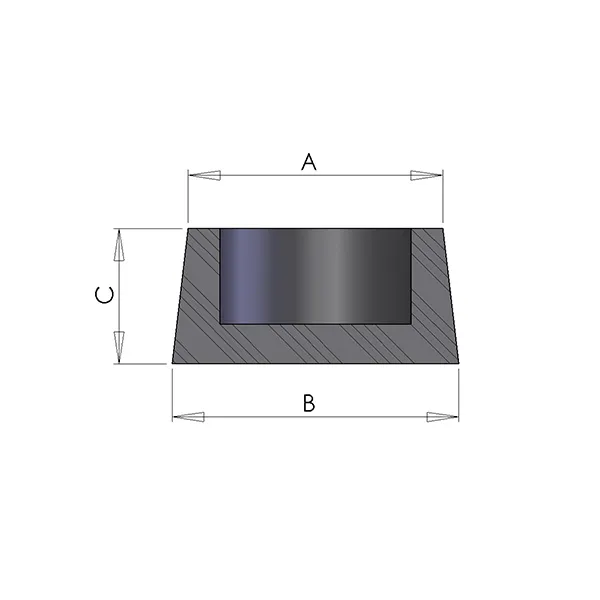

Silicone Hollow Tapered Plugs are designed to cover and protect holes of different diameters during surface treatment processes. These HSTS Silicone Plugs feature a conical and hollow design, making them lighter and more economical than solid plugs while maintaining excellent heat resistance up to 315ºC.

Key Features and Advantages of Silicone Hollow Tapered Plugs

- High temperature resistance up to 315ºC, suitable for powder coating, liquid coating and plating.

- Hollow conical design reduces material weight and cost while maintaining flexibility.

- Adapts to multiple hole diameters thanks to its tapered shape.

- Push-fit application allows fast insertion and removal for both blind and through holes.

Applications of Reusable Silicone Hollow Tapered Plugs

HSTS Silicone Hollow Tapered Plugs are used in Powder Coating, Liquid Coating, Plating, E-Coating, Anodizing and Cataphoresis. Their lightweight structure and conical shape make them perfect for masking blind or through holes efficiently.

Durability and Reusability of 315ºC Silicone Hollow Tapered Plugs

Manufactured from premium silicone, these hollow plugs combine durability, temperature resistance and reduced weight. They provide a cost-effective, reusable and sustainable masking solution for protecting components with varying hole sizes during industrial surface treatments.

Choose the HSTS – Reusable Silicone Hollow Tapered Plug (Conical) 315ºC for lightweight, precise and durable masking in high-temperature coating and anodizing applications.