Standard Masking Solutions

Silicone Double Plug – Reusable Protection up to 315ºC

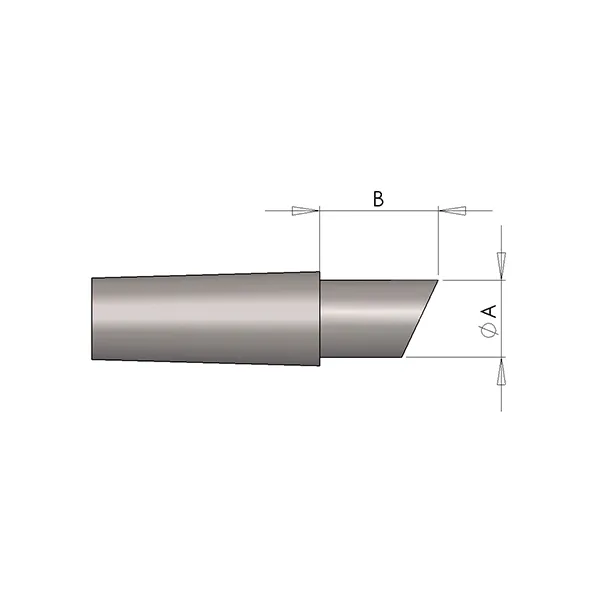

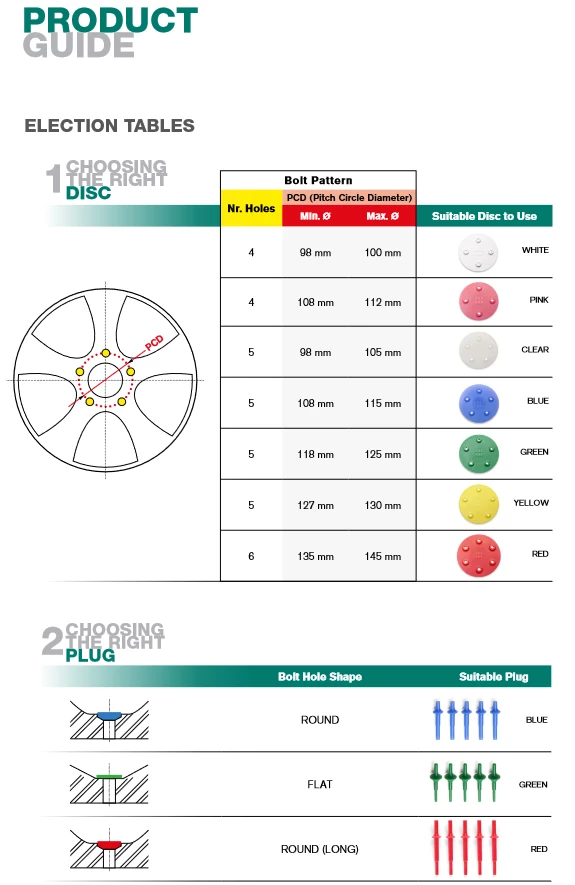

Silicone Double Plugs are designed to protect holes of two different diameters during coating and finishing processes. These UW Silicone Plugs feature a double-step conical design with integrated handle for quick application and removal. Made from high-quality reusable silicone, they are resistant up to 315ºC and provide efficient masking for blind and through holes.

Key Features and Advantages of Silicone Double Plugs

- High temperature resistance up to 315ºC, ideal for powder coating, liquid coating and plating.

- Double-step design covers two hole diameters with one plug, reducing inventory and time.

- Metric tip masks the first thread for precise protection of threaded holes.

- Integrated handle enables easy placement and removal without tools.

- Reusable and flexible, maintaining form and sealing ability after multiple cycles.

Applications of Reusable Silicone Double Plugs

UW Silicone Double Plugs are commonly used in Powder Coating, Liquid Coating, Plating, E-Coating, Anodizing and Cataphoresis. Their double-step structure makes them suitable for masking holes of different diameters, while protecting the first thread during coating or plating operations.

Durability and Reusability of 315ºC Silicone Double Plugs

Manufactured from durable silicone, these plugs maintain flexibility and precise fit after repeated high-temperature exposure. They offer a cost-effective and sustainable masking solution for industrial applications requiring multi-diameter protection and first-thread masking.