Standard Masking Solutions

Peelable Masking Paste – Hand-Peelable Air-Drying Coating

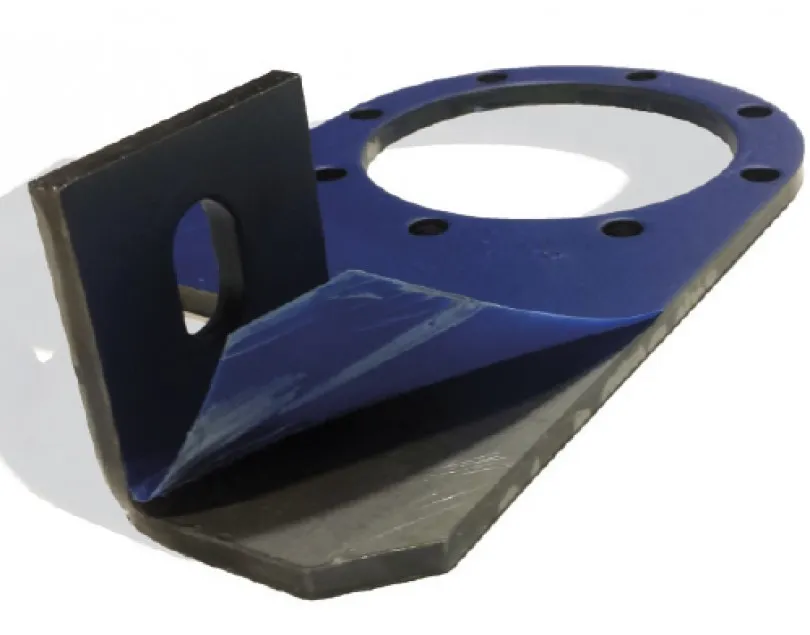

Peelable Paste is an air-drying masking coating designed to protect metallic surfaces during chemical and electrochemical processes. Applied by brush or dipping, it forms a flexible and uniform film that can be easily removed by hand without leaving residue on the substrate.

This peelable coating maintains excellent adhesion and flexibility throughout treatment cycles and withstands thermal exposure up to 180ºC. It provides reliable protection during operations where conventional silicone masking products are unsuitable.

Key Features and Advantages of Peelable Masking Paste

- Hand-peelable film removes cleanly without residue.

- Air-drying application suitable for brushing or dipping.

- Resistant up to 180ºC during thermal cycles.

- Flexible protective layer resists abrasion, bending and shaping.

- Ideal for complex geometries and surfaces that require liquid masking.

Applications of Peelable Masking Paste

This hand-peelable masking paste is widely used in:

- Chemical cleaning processes

- Etching operations

- Anodizing with chromic or phosphoric acid

- Electrodeposition and plating lines

- Surface protection during thermal treatments up to 180ºC

The paste forms a uniform barrier that protects selected areas from chemical attack, ensuring clean edges and preventing unwanted treatment of masked zones.

Performance and Reliability of Peelable Coating

Manufactured for industrial finishing processes, this coating offers dimensional stability, durability under chemical exposure and easy manual removal. It is a cost-effective and versatile masking solution for parts where tapes or silicone plugs cannot adapt.

Choose the Peelable Masking Paste for efficient, flexible and residue-free protection in chemical, anodizing and electrodeposition treatments.